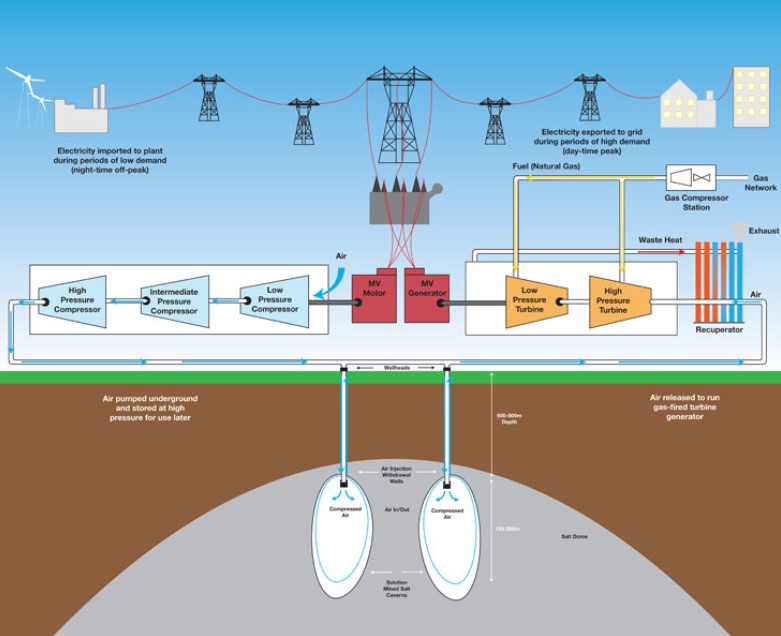

Compressed Air Energy Storage (CAES) is a way to store the energy generated at a given time, for use at another time. Energy generated during periods of low electricity consumption (off-peak) can be released to meet periods of higher demand (in the grid’s peak).

Since 1870, compressed air storage systems have been implemented to provide efficient on-demand energy demanded by industrial enterprises as well as residential consumers. Although many smaller applications exist, the first utility-scale system was introduced in 1970 with a capacity of over 290 MW. Compressed air storage systems (CAES) can be used for both small capacities and larger installations that can provide huge energy reserves for the power grid.

How do compressed air storage systems work?

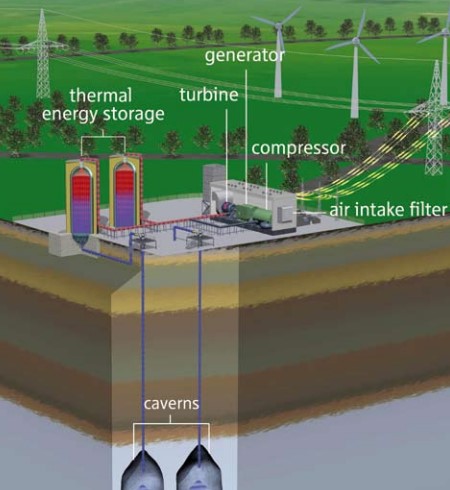

Compressed air energy storage (CAES) installations are largely equivalent to pumping-accumulating hydroelectric power stations (SHP). But instead of pumping water from a lower to upper aquifer during periods of excess energy, in a CAES installation, ambient air or other gas is compressed and stored under pressure in an underground storage or container. When electricity is needed, pressurized air is heated and expanded in an expansion turbine driving a generator to produce power.

The special feature of compressed air storage is that when it is compressed, the pressure reaches 70 bar, starting from atmospheric pressure. Standard multistage air compressors use intercoolers and aftercoolers to reduce discharge temperatures to 149 – 177°C. The temperature of the air for injection into the storage is reduced to 43 – 49°C. Therefore, the heat from the compression process is extracted or removed by an intercooler. The heat loss is compensated during the power generation phase of the expansion turbine by heating the high pressure air in the combustion chambers using natural gas fuel. As an alternative solution, the heat from the turbine exhaust gases in a recuperator can be used to heat the inlet air before the expansion cycle. The released heat, during compression, can be thermally stored before entering underground storage and used for adiabatic expansion.

Diabatic CAES method

All the proposed projects, as well as the commissioned CAES installations – in Huntorf, Germany and in McIntosh, USA, are based on the diabatic method. In their basic principle, this type of installations are conventional gas turbines, where, however, the compression of the combustion air is separate and independent from the actual gas turbine process. This leads to both of the main advantages of this method.

Since the compression ratio typically uses about 2/3 of the turbine capacity, the CAES turbine can generate 3 times more power for the same natural gas input flow. This reduces specific gas consumption as well as reducing carbon dioxide emissions by around 40 to 60%, depending on whether the waste heat is used to heat the air in a recuperator. The power efficiency is approximately 42% without and 55% with waste heat recovery. Instead of compressing the air with an additional amount of gas, the excess energy at a lower cost can be used during the grid’s off-peak periods.

Both of the aforementioned plants use single axis machines where the compressor-engine/generator-gas turbine are located on the same shaft and are connected through a gearbox. In other conceptual designs of CAES systems, the motor-compressor unit and the turbine-generator unit are mechanically separated. This enables modular expansion of the installation in terms of input and output power.

The use of waste heat energy from conventional gas turbines for the purpose of heating high-pressure air allows CAES installations to have different technological options, depending on the storage volume and pressure.

Adiabatic method

Much higher efficiency, approximately up to 70%, can be achieved if the heat from compression is recovered and used to reheat the compressed air during turbine operation, as there is no longer a need to burn additional natural gas for heating of the air.

Storage options

Regardless of the method chosen, very large storage areas are required due to the low density. The preferred locations are in man-made salt storages in deep salt caves. Salt reservoirs are characterized by several positive properties: high flexibility, no pressure losses and no reaction with oxygen in the air and salt rock. If there are no suitable salt formations, it is possible to use natural aquifers. However, to do so, tests must first be performed to determine if and how oxygen reacts with the rock and any microorganisms in the aquifer rock formation, which can lead to oxygen depletion or clogging of the reservoir’s pores. Depleted natural gas fields are also being explored for compressed air storage.

CAES power plants are a realistic alternative to pumping-accumulating hydroelectric power stations (SHP), as the capital and operating costs of already operating diabatic plants are competitive.

Contacts:

Do not hesitate to contact our specialist on email sales@atamiq.com or phone +359886163199