Landfill gas (LFG) is a natural byproduct of the decomposition of organic materials in landfills. LFG consists of approximately 50 percent methane (the main component of natural gas), 50 percent carbon dioxide (CO2), and a small amount of non-methane organic compounds. Methane is a powerful greenhouse gas, 28 to 36 times more effective than CO2 at trapping heat in the atmosphere over a 100-year period. To limit the impact of this gas on climate change, politicians and waste management operators are promoting both a significant reduction in the volume of waste going to landfills and better utilization of the methane produced.

Methane emissions from landfills

Municipal solid waste (MSW) landfills are the third largest source of human-related methane emissions in the United States, accounting for approximately 14.5 percent of these emissions. Methane emissions from MSW landfills are roughly equivalent to the greenhouse gas (GHG) emissions of about 20.3 million passenger vehicles driven in one year, or the CO2 emissions from the energy use of almost 11.9 million households in one year . At the same time, methane emissions from MSW landfills represent a lost opportunity to capture and use a significant energy resource.

When municipal solid waste is first deposited in a landfill, it goes through an aerobic decomposition stage, during which aerobic bacteria consume oxygen and convert organic matter into biomass. These processes develop on the surface at a depth of up to 1m from the waste volume. At greater depth and over time, usually within less than 1 year, anaerobic conditions are established and methane-producing bacteria begin to decompose the waste and generate methane. Bacteria break down waste from landfills in four phases. The composition of the gas changes with each phase and landfill waste can go through several phases of decomposition simultaneously. Time after disposal (total time and phase duration) varies depending on landfill conditions.

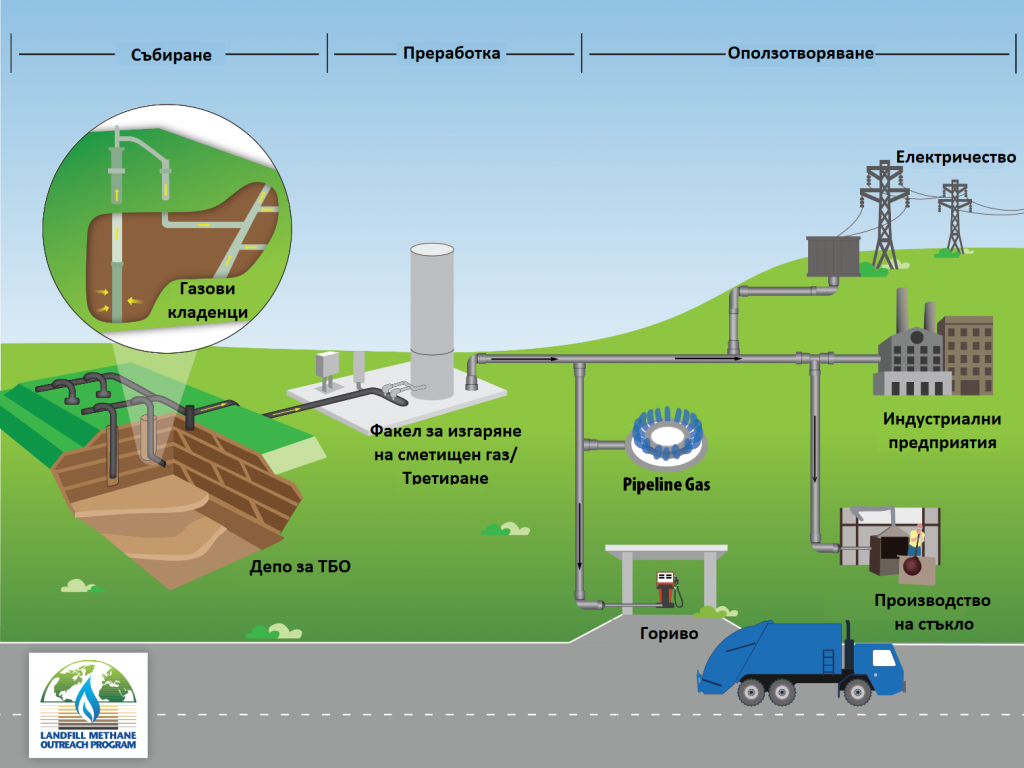

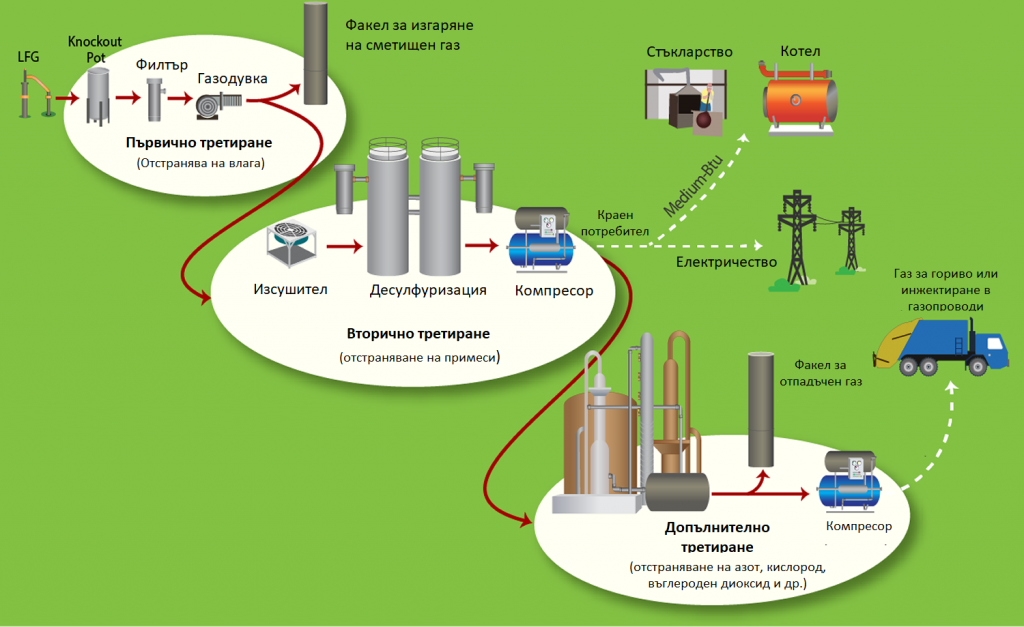

Landfill gas capture and treatment

Instead of being released into the air, landfill gas can be captured, converted and used as a renewable energy source. The use of LFG helps reduce odors and other hazards associated with landfill gas emissions, prevents the migration of methane into the atmosphere, and contributes to the reduction of local smog and global climate change. In addition, energy projects for LFG generate income and create jobs in the community and beyond.

Types of energy projects for the utilization of landfill gas

There are many options for converting landfill gas into energy. The different types of energy projects for are grouped below into three broad categories – electric power generation, direct use of average Btu gas, and renewable natural gas.

Electricity production

About 68% of currently operating landfill gas (LFG) energy projects generate electricity. A variety of technologies, including reciprocating internal combustion engines, turbines, microturbines, and fuel cells, can be used to generate electricity for on-site use and/or sale to the grid. The reciprocating engine is the most commonly used technology for LFG-to-electricity applications due to its relatively low cost, high efficiency, and size ranges that complement many landfill gas production. Gas turbines are typically used in larger LFG power projects, while microturbines are typically used for smaller volumes of LFG and in niche applications.

Cogeneration projects, also known as combined heat and power (CHP), use LFG to generate both electricity and heat, usually in the form of steam or hot water. Several CHP projects using engines or turbines have been installed in industrial, commercial and institutional operations using engines or turbines. Efficiency gains from heat capture in addition to power generation can make this type of technology very attractive. This heat can be sent via heat exchangers to customers as well as for heating biomass for more efficient methane production.

Direct use of landfill gas

Direct use of LFG to offset the use of another fuel (eg, natural gas, coal, or fuel oil) occurs in about 16 percent of currently operating projects. LFG can be used directly in a boiler, dryer, furnace, greenhouse or other heat application. In this case, the gas is supplied directly to the nearby customer for use in combustion equipment as a replacement or supplemental fuel. Only limited condensate removal and filtration treatment is required, although some modifications to existing combustion equipment may be required.

LFG can also be used directly to evaporate leachate. Evaporation of leachate using LFG is a good option for landfills where disposal of leachate to a water reclamation facility is not available or is expensive. LFG is used to evaporate the leachate into a more concentrated and more easily disposed volume of wastewater.

Innovative direct uses of gas include ceramic firing and glass furnaces; power supply and heating of greenhouses; and evaporation of waste paint. Current industries using LFG include automotive manufacturing, chemical manufacturing, food and beverage processing, pharmaceuticals, cement and brick manufacturing, wastewater treatment, consumer electronics and products, paper and steel manufacturing, and prisons and hospitals.

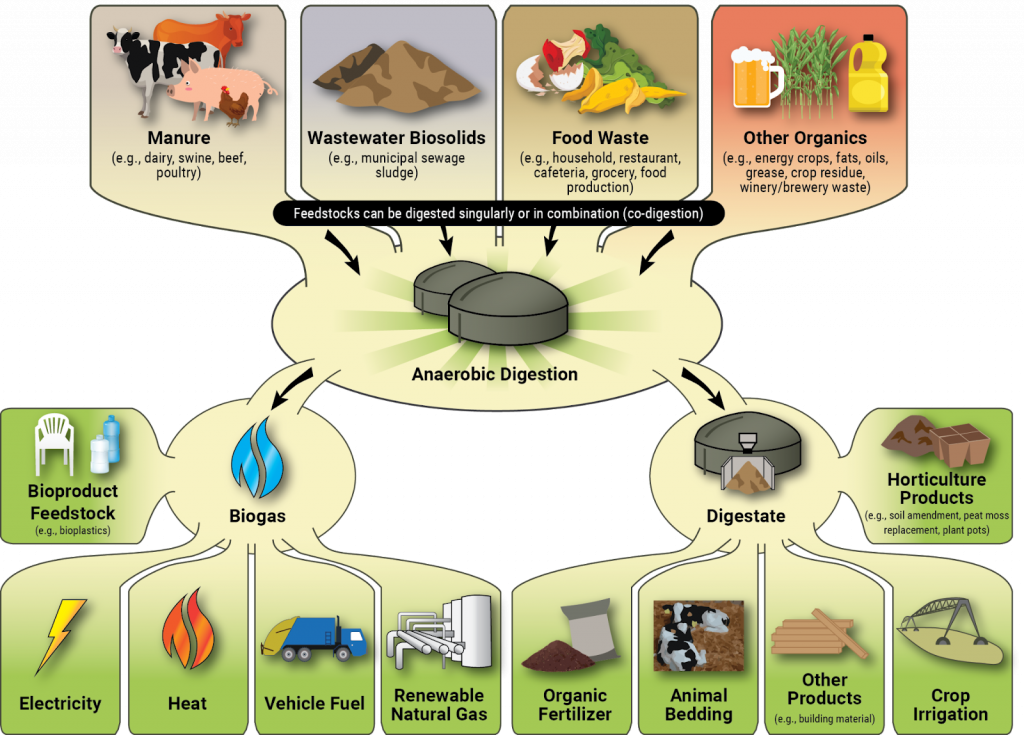

Biogas

Landfill gas (LFG) can be upgraded to renewable natural gas (RNG), a high Btu gas, through processing processes by increasing the methane content and, conversely, decreasing the CO2, nitrogen and oxygen content. RNG can be used in place of fossil natural gas such as pipeline grade gas, compressed natural gas (CNG) or liquefied natural gas (LNG). About 16 percent of currently operating LFG energy projects generate RNG.

The possibilities for using biogas include thermal applications, to generate electricity or as a fuel for vehicles. RNG can be used locally at the location where the gas is produced, or it can be injected into natural gas transmission or distribution pipelines for delivery to another location.

Source: https://www.epa.gov/

Contacts:

If you also have a renewable energy production project, do not hesitate to contact our specialist at email sales@atamiq.com or phone +359886163199