The increasing production of electricity from solar systems has created a demand for rapid regulation of the frequency of electrical grids. The electrode boiler can be used for primary regulation with less than 30 seconds response time from minimum to maximum load.

The conversion of electrical energy into heat makes it possible to accumulate renewable energy in periods of overproduction. This allows renewable energy sources to run continuously and green energy to replace fossil fuels.

Electrode and steam boilers offer cost-effective, low-carbon steam for process heat. Although the application of these technologies is still limited, international experience with electrode boilers shows that they are economically viable in many situations. The integration of electric water heaters with thermal storage can support the flexibility and resilience of the electricity system, allowing for the increased use of intermittent renewable electricity.

An electric steam boiler produces steam using electricity as fuel, not fossil fuels or biomass fuels. Electrically generated steam or hot water is suitable for many processes, including food and material production.

These boilers are usually installed in various commercial buildings such as hospitals. The advantages of electric steam and water boilers include simple and easy operation and significantly lower capital costs.

Electrode and electric steam generators are almost 100% efficient and can closely follow changing loads. They can also have relatively low initial capital costs and low maintenance and operating costs – especially when compared to solid fuel boilers. This means that although their ‘fuel’ costs are higher per unit than traditional fuels, in some cases the total operating costs can be relatively low.

Another important feature and main advantage of electric boilers is that they can be located much closer to the place in the installation where the steam is needed. This further reduces capital costs by minimizing steam distribution piping. Reducing or eliminating heat losses in pipelines, in turn, reduces operating costs. The hazards of flues, fuel tanks and fuel lines are also eliminated, providing significant safety and space savings. The small size and ease of use can also make electric boilers a practical choice for commercial establishments.

Technical features of electrode boilers

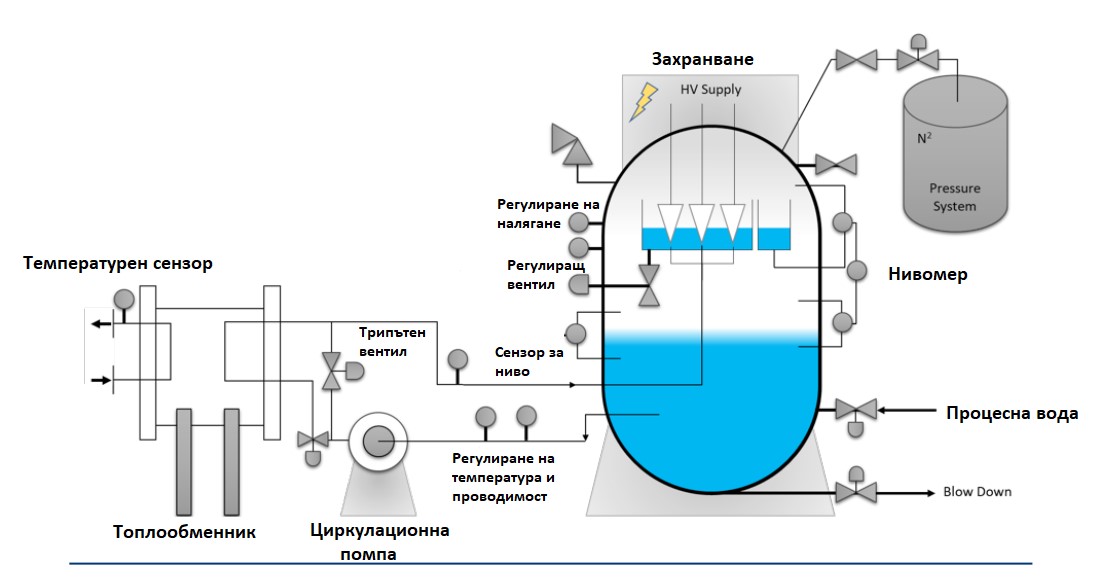

Electrode steam generators produce steam by passing an electric current directly through the water between high-voltage boiler electrodes. The conductivity of water allows a high current density to produce heat in the water and generate steam. The capacities of this type of boilers vary from 30 kW to 30 MW and produce steam at a pressure of up to 40 bar(g).

Modern electrode steam generators work at distribution voltages, which leads to the elimination of the need for transformers. This type of boiler uses power electronics to allow precise output control and minimize the use of heavy contactors. Steam flow is controlled by variable frequency feed pumps that continuously modulate steam output to meet process needs. A stepless reduction of 100:1 is possible. Electrode steam generators and boilers can be designed for both single-phase and three-phase operation.

Efficiency

Electrode boilers transfer energy directly to the water, which makes them very compact and therefore use only 20% water compared to an equivalent fuel boiler. Compared to fuel boilers, which have high thermal inertia, electrode boilers have greater flexibility and very high ramp-up rates, and full steam removal can be achieved much faster, typically in less than a minute.

Improved design and device

Improvements in the design of the electrode steam generator reduce the maintenance problems of older designs, which reduces operation and maintenance costs.

- Modern electrode boilers do not need dielectric barriers and pre-treatment of water, which is required for earlier types of boilers. Conductivity controllers automatically manage purging to keep water conductivity at ideal levels.

- The performance of modern electrode boilers is modified by controlling water throughput using integrated feedwater systems and frequency-controlled feed pumps. These features eliminate the need for adjustable electrodes and electrode shield positioning systems. In conditions of low or no water, the circulation pump stops, which causes the boiler to stop and, in turn, increases the safety of operation at a low water level.

Electrode water heaters

Electrode boilers can be configured to produce hot water rather than steam. The basic design is similar, but for hot water production, the boiler feedwater is circulated internally at a rate that avoids reaching steam production temperatures at the boiler’s operating pressure.

Advantages

- Low capital costs – Electrode boilers are compact and can be installed close to heat loads. Capital costs are about half that of coal-fired boilers, where 90% of life-cycle operating costs are energy costs.

- Durability – With few components and only water at high temperature, there is little thermal stress and very little heat loss.

- Efficiency – With negligible heat losses, 99% of electricity is available as process heat.

- Safety – Water loss self-regulates the electrode current ie. the lack of water supply prevents the element from working. Unlike fuel boilers, no part of the electrode or electric boiler is at a temperature higher than that of the steam.

- Grid integration – As power grids require faster response, electrode boilers can offer significant responsiveness in peak, load balancing and standby applications

- Reduced downtime – Fewer components and faster annual inspections (less than a week) result in lower O&M costs.

- Dry Steam – The vertical structure of the boiler produces dry steam – typically around 99.8%.

Contacts:

Do not hesitate to contact our specialist on email sales@atamiq.com or phone +359886163199