Freely available stormwater, with a low mineral content, can be used in production and processing operations. Not only is it available for free, but it also offers technical advantages: Rainwater is low in dissolved minerals and therefore soft by nature – it leaves very low levels of mineral deposits or residues in the process equipment in which it is used.

For these reasons, an increasing number of companies are installing rainwater harvesting system to use in their processes. Before rainwater is used as circulating water in an industrial enterprise, the water must undergo several treatment steps including treatment and disinfection.

Rainwater collection and use

The first stage of this process, before processing begins, is the collection and storage of rainwater. There are many ways to collect rainwater, from special dams to roof gutter systems connected to water tanks. When installing a stormwater harvesting system businesses must ensure that the system complies with regulatory requirements. Stored water must also be treated before reuse to ensure safety.

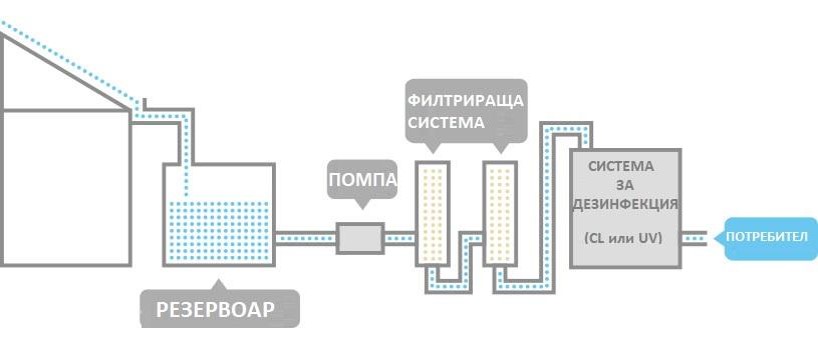

Stormwater harvesting systems can be installed as above-ground or underground tanks to meet the requirements of industrial needs. The volume of the tanks is different, depending on the needs of the enterprise – from 1000 liters to over 1,000,000 liters. The operation of the rainwater collection and subsequent treatment system is automated in order to reduce operational activities.

The preliminary stage of rainwater treatment usually involves an initial mechanical treatment of the water with filters to prevent leaves and debris from collecting with the water. Thanks to this preliminary separation of mechanical impurities in the stormwater collection tank, a minimum amount of impurities is allowed to settle to the bottom and form sludge.

Possibilities for the purification of stormwater

There are two main disinfection technologies in rainwater treatment:

- Chlorine disinfection – an excellent solution when large quantities of water will be stored for later use and in general industrial applications.

- UV Disinfection – This treatment is typically used when smaller amounts of stored water are required for a shorter period of time and is a great alternative for industrial applications sensitive to corrosion from chlorine exposure.

Industrial facilities located in regions that experience sporadic to heavy rainfall can significantly reduce their water costs by implementing a stormwater harvesting system. The treatment and disinfection of rainwater is necessary to make the rainwater compliant with national regulations and safe for the installations.

Although stormwater looks clean to the naked eye, it is not safe to use until it is treated. Stormwater is rich in pathogens and can cause illness or infections if it comes into contact with open wounds or is ingested.

Treatment process

Rainwater can contain pollution, animal excrement, and other particles that are harmful to humans, plants, and animals. Collected rainwater must therefore be treated before it is safe for business use. There are two main steps for rainwater purification: mechanical filtration and disinfection with chlorine or UV systems.

Filtering

The first step in rainwater treatment involves removing sediment and small particles.

Rainwater collected from roofs moves through a pipe to a storage tank or pit. At the bottom of the tank, all particles settle. A float mechanism triggers the system to begin pumping, or a drop in line pressure indicates the need for treatment and immediate water transfer.

Before the disinfection process, mechanical filtration is performed. Filtration consists of removing solids 1-5 microns in size using a sieve or sand filter. It is good that the filters have the option of self-cleaning.

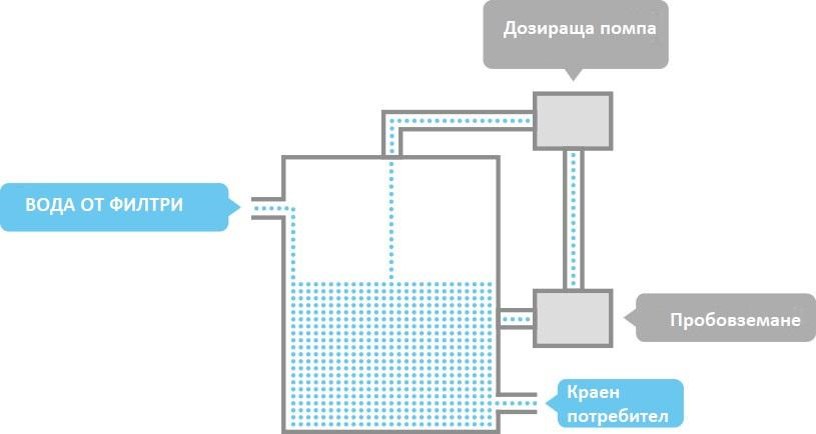

Disinfection with chlorine

Adding chlorine to water is an easy and effective way to decontaminate filtered rainwater. Chlorine treatment is an ideal solution for rainwater that needs to be stored for future use. Stormwater complies with treatment regulations at all times as a sampling system and automatic chlorine concentration adjustment is installed.

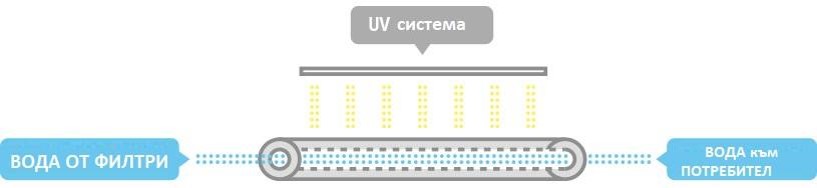

UV disinfection

Ultraviolet light is an alternative method of disinfection. It works by destroying and damaging the cells of pathogens. With this type of disinfection, the requirement is that the rainwater be practically sediment-free. If rainwater is not filtered, “shading” can occur, where sediment blocks UV light rays, reducing disinfection effectiveness.

Advantages of UV sterilization

- UV bulbs have a lifespan of 12 months to 2 years.

- UV modules can handle high flow rates.

- Water treated with ultraviolet light can be used immediately after treatment.

- UV-treated rainwater is less of a corrosion risk for exposed metals.

Areas of application of treated rainwater

Rainwater can be used as softened process water for applications that do not require potable water quality. Such cases are the following cases:

- Cooling water

- As a drilling fluid

- For irrigation

- For filling fire-fighting water tanks

- For cleaning

Key benefits for industry

Industrial enterprises can reduce their operational costs of water consumption, become more sustainable and increase their environmental value in the context of ESG methodology. Additional benefits for industrial installations are:

- Softened rainwater reduces problems caused by limescale

- Investment and operating costs of water softening equipment are reduced or completely eliminated

ATAMIQ’s engineering team is available to advise your business on how to optimally use stormwater as an ecological solution to improve the public image of the company and environmentally responsible operators to reduce water consumption from the network.

Contacts:

Do not hesitate to contact our specialist on email sales@atamiq.com or phone +359886163199